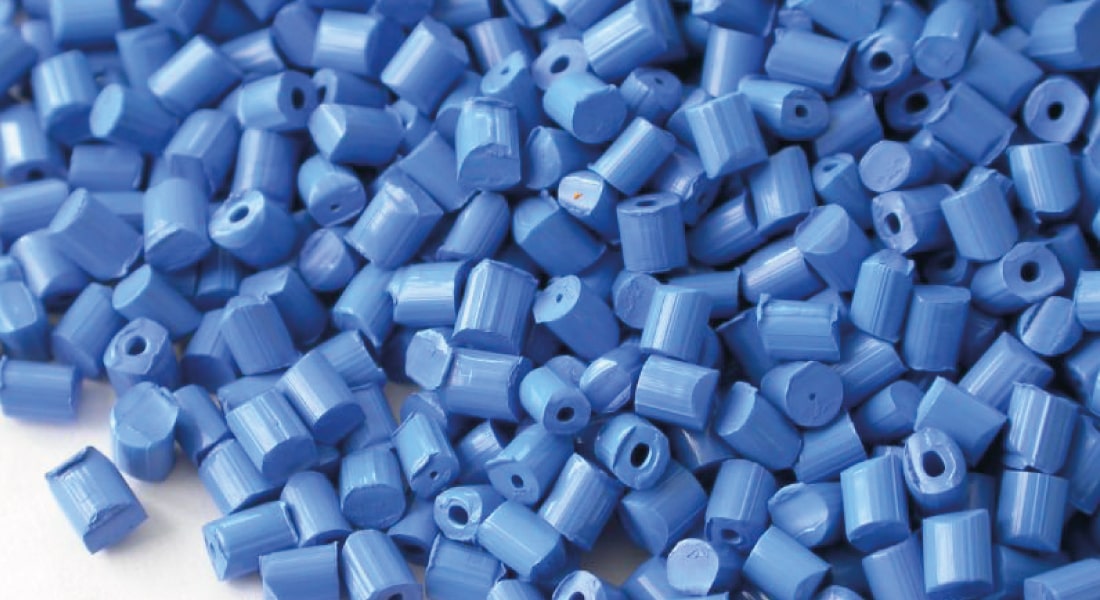

Low-Density Polyethylene

Low-Density Polyethylene (LDPE) is a durable thermoplastic, created in 1933 through a high-pressure process. It has remained widely used globally, particularly in packaging since the late 1940s. LDPE’s branched structure, flexibility, chemical resistance, and low production cost make it ideal for various applications.